This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

PANELO ROOF & CEILING PANELS

PANELO LOAD-BEARING ROOF PANELS

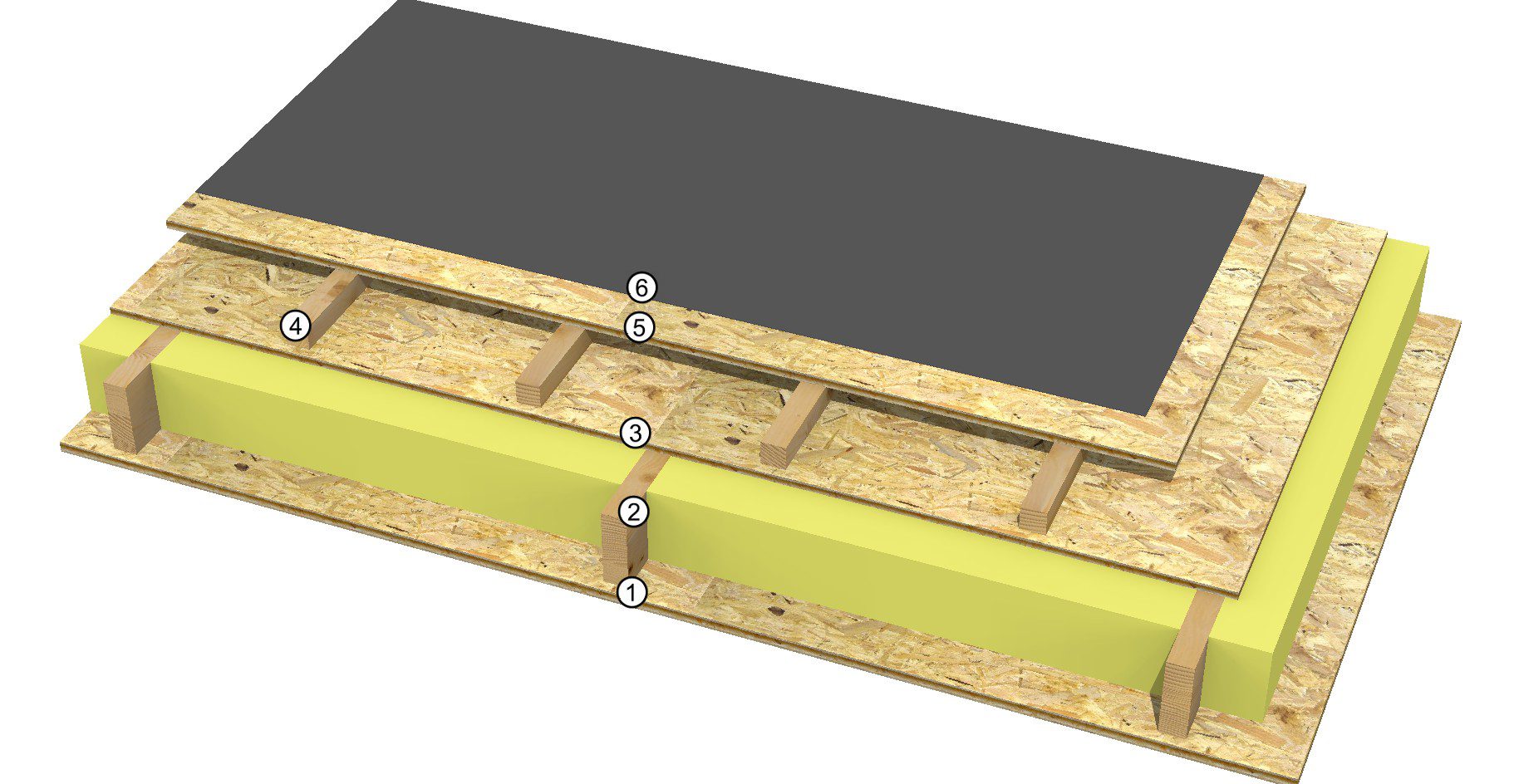

Version 1 – LVL-PUR-OSB

(illustrative; no battens or roof sheeting attached)

Version 2 – OSB-PUR-OSB

(illustrative; no battens or roof sheeting attached)

PANELO closed timber frame load-bearing panels share similarities with SIP panels but are technically far more advanced. Each panel comprises a load-bearing timber frame, durable LVL and OSB boards, and closed-cell PUR insulation. The insulation is injected in liquid form using specialized technology, creating a rigid, airtight composite structure.

The panels are manufactured in a precut format, featuring framed roof window and chimney openings customized to project specifications — including dimensions, U-values, and structural load requirements. PANELO panels meet low-energy and passive house standards while maintaining a slim profile, maximizing usable interior space within the building.

Maximum size 12 x 3,4 m.

STANDARD CONFIGURATIONS FOR LOAD-BEARING ROOF PANELS (RP)

| No | Panel (layers mm) | Thick. (mm) | U-value W/(m²K) |

|---|---|---|---|

| 1 | RP 15-145-15 (OSB-PUR-OSB) | 175 | 0,18 |

| 2 | RP 15-170-15 (OSB-PUR-OSB) | 200 | 0,16 |

| 3 | RP 15-195-15 (OSB-PUR-OSB) | 225 | 0,14 |

| 4 | RP 15-220-15 (OSB-PUR-OSB) | 250 | 0,12 |

| 5 | RP 15-245-15 (OSB-PUR-OSB) | 275 | 0,11 |

| 6 | RP 27-145-15 (LVL-PUR-OSB) | 181 | 0,18 |

| 7 | RP27-170-15 (LVL-PUR-OSB) | 206 | 0,16 |

| 8 | RP 27-195-15 (LVL-PUR-OSB) | 231 | 0,14 |

| 9 | RP 27-220-15 (LVL-PUR-OSB) | 256 | 0,12 |

| 10 | RP 27-245-15 (LVL-PUR-OSB) | 281 | 0,11 |

PANELO Roof Panels Align with the Future Homes Standard (FHS)

With PANELO roof panels, you're not just meeting the Future Homes Standard—you're building beyond it. Our composite timber panels deliver exceptional thermal performance, airtightness, and structural integrity in one prefabricated system that saves time, labour, and space.

Ready for Future Homes Performance Targets

The Future Homes Standard (coming fully into force in 2025) requires homes to be 75–80% more energy efficient than those built under the 2013 regs.

PANELO roof panels are pre-engineered to deliver low U-values (e.g. 0.11 W/m²K or better) and excellent airtightness, helping buildings exceed Part L and prepare for net zero-ready construction. No extra insulation layers or additional membranes are needed to meet the thermal envelope criteria.

Closed-Cell PUR Insulation – Superior Thermal and Airtight Performance

PANELO panels use factory-injected PUR foam, which fully fills cavities and eliminates thermal bridging and air gaps. Unlike mineral wool or EPS SIPs, PUR offers:

- Higher insulation performance per mm

- Long-term dimensional stability

- Low moisture absorption — essential for UK’s damp climate

This results in a rigid, airtight composite, simplifying compliance with air leakage tests.

Fast & Precise On-Site Assembly

Panels arrive precut, with framed openings for roof windows, chimneys, and services. This:

- Reduces on-site labour

- Speeds up weatherproofing (dry shell within days)

- Minimizes construction errors that often lead to thermal and acoustic bridges

Slim Build-Up = More Internal Volume

While complying with high insulation standards, PANELO roof panels maintain a slim profile, maximizing usable loft or second-floor space without increasing ridge height—an important factor for planning compliance in urban and conservation areas.

Design Flexibility for Architects

PANELO’s structural capabilities allow:

- Long spans

- Vaulted ceilings

- Flat or pitched roof configurations

- Integration with timber, steel, or hybrid structures

Your design freedom stays intact while meeting demanding performance specs.

Compliance Support

We provide:

- Full technical datasheets (U-values, fire ratings, loading data)

- Structural calculations

- Assistance with SAP assessments and PHPP (Passive House Planning Package) if required

PANELO ROOF PANELS